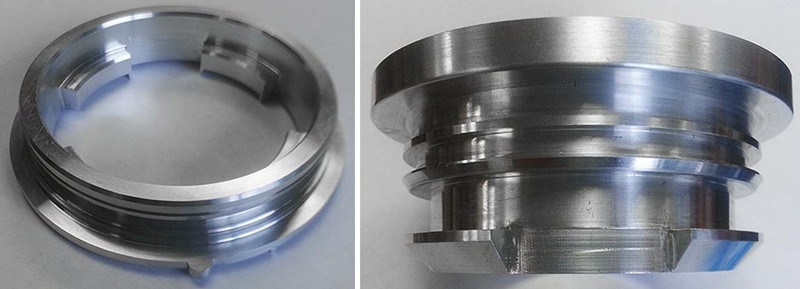

High Precision Lost Wax Steel Casting

Deskripsi Produk

Baja tahan karatyaiku paduan baja kanthi kandungan kromium minimal 10,5% kanthi massa.Stainless steel digunakake ing ngendi loro sifat baja lanresistance karatdibutuhake.Dadi kaya wesi baja cast liyane, stainless steel digunakake akeh bahan kanggo produksi casting.

Casting stainless steel digawe ing pengecoran baja kita utamané deningpengecoran sol silikaproses.Casting silika sol palingcasting investasi tlitiproses.Proses casting stainless steel melu leleh logam, ngecor, lan nggawe komponen kualitas karo panas pancet utawa reresik.Nalika komponen casting normal ora bisa kanggo ngirim kekuatan cukup lan fitur tahan kejut banjur casting stainless steel mung dijupuk pilihan apik liwat liyane.Proses iki bisa ngasilake casting wangun net tliti dhuwur tanpa mesin.Biasane, kita bisa ngontrol casting stainless steel presisi kasebut kanthi tingkat toleransi CT5-6.Kauntungan liyane yaiku, kanthi proses iki, pengecoran kita bisa nyedhiyakake casting stainless steel tanpa cacat.

Kelas Material Umum sakaPengecoran Stainless Steel

SS304:Baja austenit sing paling akeh digunakake, bisa uga diarani stainless A2.

SS316:Baja austenit paling umum kaloro, uga diarani stainless A4.SS316 digunakake utamané kanggo resistance tambah kanggo karat.

SS304L & SS316L(superaustenitic stainless steel): Ing [L" tegese isi karbon saka wesi ing ngisor 0,03%, kang nyuda efek sensitization disebabake suhu dhuwur melu welding.Dibandhingake karo seri 300, nuduhake resistensi sing luwih apik kanggo retak karat.

17-4 PH:Baja tahan karat martensitik presipitasi sing paling umum, sing nggunakake 17% kromium lan 4% nikel.

Perawatan lumahing saka Castings Stainless Steel

Ditembak Blasting: Digunakake kanggo mbusak kulit oksida ireng lumahing sawise casting produk stainless steel.

Pickling & Perawatan Pasif: Pickling minangka cara perawatan kimia kanggo ngilangi rereget lumahing kaya kulit oksida, teyeng, bintik welding, lsp.Lan passivation proses sing mbentuk lapisan protèktif kromium KALUBÈRAN anyar, mangkono kanggo nambah kemampuan anti-oksidasi saka castings stainless steel.

Electropolishing: Digunakake kanggo mbusak burrs cilik lumahing lan nambah padhange casting stainless steel.

Pangilon Polishing: A jenis cara polishing lumahing sing bisa entuk lumahing Gamelan lan mencorong kaya Rampung pangilon.

Aplikasi saka Stainless Steel Casting

Kanggo sifat fisik unik saka stainless steel, Casting stainless steel dadi kanggo sawetara saka sudhut industri, utamané ing lingkungan abot.Ing ngisor iki aplikasi utama casting stainless steel

pabrik kita